Jun 04, 2025

ISO Clean Room Standards

ISO Clean Room Standards: A Complete Guide to ISO 14644 Compliance in Cleanroom Design and Operation

Introduction: Why ISO Clean Room Standards Are Essential

Cleanrooms are critical environments used across pharmaceutical manufacturing, biotechnology, aerospace, microelectronics, and medical device production. These spaces are engineered to control airborne contamination and ensure a consistently clean environment for sensitive processes. At the core of cleanroom design, construction, and operation are the ISO clean room standards, a globally recognized framework established by the International Organization for Standardization. These standards provide clear, measurable criteria for classifying, designing, monitoring, and maintaining cleanrooms to ensure product integrity, regulatory compliance, and operational excellence.

The ISO 14644 series has become the international benchmark for cleanroom practices, replacing outdated systems like Federal Standard 209E in the United States and harmonizing global requirements into a unified standard. Unlike national or application-specific regulations, ISO standards apply across industries, making them ideal for multinational operations that must maintain consistent cleanliness and compliance across multiple regions and product lines.

ISO clean room standards cover more than just particle counts—they address design layouts, airflow dynamics, surface materials, monitoring strategies, testing methods, and personnel behaviors. Together, these guidelines form a comprehensive approach to contamination control. For any company seeking to build or operate a controlled environment, understanding the scope and application of ISO 14644 is essential. It is not merely a requirement—it’s the foundation upon which clean, compliant, and high-performing facilities are built.

What Is ISO 14644?

ISO 14644 is a family of international standards that governs the classification, design, testing, and operation of cleanrooms and associated controlled environments. First published in 1999, the standard was developed to replace the U.S. Federal Standard 209E, offering a more modern, metric-based, and internationally applicable approach to airborne particulate control. Over time, the ISO 14644 series has expanded into multiple parts, each addressing a specific facet of cleanroom performance.

The most well-known part, ISO 14644-1, defines the classification of air cleanliness by particle concentration. It outlines nine ISO classes, from ISO Class 1 (the cleanest) to ISO Class 9 (the least stringent), based on the allowable number of particles per cubic meter at various particle sizes. This part serves as the foundation for specifying the cleanliness level a cleanroom must maintain to support its intended process.

ISO 14644-2 complements this by establishing requirements for monitoring and maintaining air cleanliness over time. It outlines procedures for routine testing, alarm thresholds, trending analysis, and frequency of requalification based on risk. This ensures that a cleanroom doesn’t simply meet ISO standards at startup—but remains in control during normal operation.

Other critical parts include ISO 14644-3, which defines the testing methods for air velocity, pressure differentials, filter integrity, and airflow visualization. ISO 14644-4 addresses the design and construction of cleanrooms, covering layout planning, HVAC systems, surface materials, and pressure cascades. ISO 14644-5 focuses on operational aspects, including personnel behavior, gowning protocols, cleaning procedures, and contamination control during active manufacturing.

Additional parts like ISO 14644-6 define terminology, ISO 14644-7 addresses separative devices like isolators and RABS (Restricted Access Barrier Systems), ISO 14644-8 focuses on airborne molecular contamination, and ISO 14644-9 and -10 deal with surface cleanliness by particle concentration and chemical concentration respectively.

Together, these standards offer a complete blueprint for the creation and ongoing management of cleanrooms. By adopting ISO 14644, organizations gain a structured framework that supports consistency, traceability, and global regulatory alignment—making it easier to meet compliance expectations in diverse markets and product categories.

Key ISO Standards for Cleanroom Design and Certification

The ISO 14644 series is composed of several distinct but interconnected parts, each contributing to the creation and maintenance of cleanroom environments. Understanding the role of each part is essential for cleanroom designers, operators, and quality assurance teams. These standards not only provide the baseline for certification but also offer detailed guidance on sustaining compliance throughout the cleanroom’s lifecycle.

ISO 14644-1: Classification of Air Cleanliness by Particle Concentration

This is the foundational standard that defines the different ISO classes (1 through 9) based on the concentration of airborne particles per cubic meter. It sets the performance thresholds used to classify cleanrooms and outlines the procedures for measuring and validating particle counts using calibrated instruments. This standard is critical for initial qualification and serves as the benchmark for ongoing monitoring.

ISO 14644-2: Monitoring to Provide Evidence of Cleanroom Performance

This standard outlines the requirements for routine monitoring of cleanrooms and associated environments. It includes criteria for establishing monitoring plans, sampling locations, frequencies, alert/action levels, and response protocols. It emphasizes risk-based approaches to monitoring and ensures that cleanrooms remain compliant over time—not just at startup.

ISO 14644-3: Test Methods

Part 3 provides detailed instructions on how to test cleanroom performance, including methods for evaluating airflow velocity, direction, HEPA filter integrity (smoke tests), differential pressure, temperature, humidity, recovery rates, and airflow visualization (e.g., smoke studies). These tests are essential during qualification (IQ/OQ/PQ) and for troubleshooting issues during operation.

ISO 14644-4: Design, Construction, and Start-Up

This section addresses the principles of cleanroom design and construction. It includes guidance on zoning, pressure cascades, HVAC layout, materials selection, finishes, and startup protocols. It ensures that cleanroom infrastructure is capable of supporting the intended ISO classification before operational processes begin.

ISO 14644-5: Operations

Part 5 covers operational protocols, including personnel hygiene and behavior, gowning procedures, material handling, cleaning and disinfection, and contamination control during process activities. It bridges the gap between infrastructure and SOPs, making it an essential standard for daily compliance and audit readiness.

Together, these standards provide the full picture of what it takes to design, build, qualify, and operate a compliant cleanroom. Regulatory bodies such as the FDA, EMA, and WHO often reference ISO 14644 in their own guidance documents, making familiarity with these standards a practical necessity for regulated manufacturers.

Designing a Cleanroom to Meet ISO Standards

Designing a cleanroom that complies with ISO 14644 standards requires more than just specifying HEPA filters and airflow rates. It involves a comprehensive strategy that integrates architecture, mechanical systems, process workflows, and human behavior into a cohesive, contamination-controlled environment. A cleanroom’s ability to maintain its designated ISO classification is determined long before construction begins—during the planning and design phase.

Layout and Zoning

The first design consideration is cleanroom zoning. Higher ISO classifications should be located at the core of the facility, surrounded by buffer areas of progressively lower classifications. This supports directional airflow and contamination containment. Airlocks, gowning rooms, and pass-throughs must be integrated into the design to prevent direct flow between classified and unclassified areas.

HVAC Design

Air handling systems are central to cleanroom performance. HVAC units must be designed to support the required number of air changes per hour (ACH), maintain temperature and humidity within defined tolerances, and ensure proper pressure differentials between rooms. High-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters are selected based on the ISO class target. Airflow may be unidirectional (laminar) or non-unidirectional (turbulent), depending on the classification and process needs.

Pressure Cascades

Properly engineered pressure cascades prevent the infiltration of contaminated air into cleaner areas. For example, an ISO Class 5 room will typically be held at a higher pressure than the adjacent ISO Class 7 or 8 background. Door interlocks and differential pressure monitors ensure that airflow direction is maintained, especially in critical areas.

Materials and Finishes

Surfaces must be non-porous, smooth, and easy to clean. Common materials include stainless steel, epoxy-coated walls, and non-shedding ceiling tiles. Joints and corners should be sealed or curved to eliminate areas where particles or microbes could accumulate. Flooring must be durable, chemical-resistant, and seamless to withstand cleaning and disinfection routines.

Workflow Integration

Cleanroom design must account for how personnel, materials, and waste move through the space. Unidirectional flows reduce cross-contamination risk. Separate entry and exit paths, dedicated gowning zones, and clearly defined workflows are key to maintaining cleanliness levels and supporting ISO 14644-5 operational guidelines.

Monitoring and Control Systems

Environmental Monitoring Systems (EMS) and Building Management Systems (BMS) should be integrated during design, not added later. These systems enable real-time monitoring of particle counts, pressure, temperature, and humidity—ensuring the cleanroom remains in compliance during all phases of operation. ISO 14644-2 provides the framework for monitoring strategies.

Designing to ISO standards from the ground up reduces the risk of compliance gaps, facilitates faster validation, and lowers long-term operating costs. Prefabricated cleanroom systems from providers like G-CON are engineered with these design principles in mind—offering prevalidated, ISO-compliant environments that support fast deployment and reliable operation.

Certification and Validation Under ISO 14644

Certification under ISO 14644 is a critical milestone in the cleanroom lifecycle. It confirms that a cleanroom meets the required air cleanliness standards for its designated ISO classification and is fit for its intended use. However, ISO certification is not a one-time event—it must be supported by structured validation, monitoring, and periodic requalification to ensure long-term compliance.

The initial certification process begins with Installation Qualification (IQ), which verifies that all cleanroom components—HVAC units, HEPA filters, walls, ceilings, doors, controls—have been installed according to design specifications. This phase involves documentation review, physical inspection, and basic system checks.

Next comes Operational Qualification (OQ), which tests cleanroom systems under controlled conditions to confirm that they perform within expected parameters. This includes airflow velocity measurements, particle counts, pressure differential validation, and HEPA filter integrity testing. Testing follows the protocols outlined in ISO 14644-3, which details methods for assessing room performance.

The final step, Performance Qualification (PQ), verifies that the cleanroom operates effectively during normal use. This means testing under real process conditions with equipment and personnel present. Particle concentrations must remain within ISO 14644-1 limits “in operation,” not just “at rest.” PQ also includes verifying that personnel practices, gowning, cleaning, and monitoring procedures support consistent performance.

Once certified, a cleanroom must undergo routine monitoring as outlined in ISO 14644-2. This includes real-time or periodic particle counting, differential pressure tracking, and environmental condition logging (temperature, humidity). Data must be reviewed for trends and deviations, and corrective action must be taken if results exceed established action levels.

Requalification is required at defined intervals—every 6 months for ISO Class 5 and annually for ISO Class 6–8, or sooner if changes are made to the facility, systems, or processes. Events such as equipment upgrades, HEPA filter replacement, or process reconfiguration may trigger partial or full requalification.

Cleanroom suppliers like G-CON support certification through Factory Acceptance Testing (FAT), performed before delivery. These tests confirm that the prefabricated cleanroom meets airflow, filtration, and pressure performance targets. Upon installation, Site Acceptance Testing (SAT) and streamlined IQ/OQ documentation accelerate final qualification and reduce project risk.

By following ISO 14644’s structured approach to validation and certification, organizations ensure that their cleanrooms not only start compliant—but stay compliant.

ISO Standards vs. Other Cleanroom Regulations

While ISO 14644 is the global gold standard for cleanroom classification and environmental control, it is often used alongside other regulatory frameworks that govern specific industries, regions, or product types. Understanding how ISO standards intersect with other guidelines is essential for organizations operating in regulated sectors.

ISO vs. FS 209E

Before ISO 14644, cleanrooms in the U.S. were classified under Federal Standard 209E, which used particle counts per cubic foot. ISO replaced FS 209E with a more granular, metric-based system, adding more classification levels and accommodating a wider range of particle sizes. Though FS 209E is now obsolete, some facilities and stakeholders still reference legacy classes like “Class 100” (equivalent to ISO Class 5), which can cause confusion.

ISO vs. EU GMP Annex 1

ISO 14644 focuses on airborne particle concentration, while EU GMP Annex 1 applies specifically to sterile medicinal product manufacturing. Annex 1 uses Grades A–D to describe controlled environments and includes microbial limits, gowning expectations, and risk-based monitoring strategies. For example, Annex 1 specifies that Grade A corresponds to ISO Class 5, but also imposes stricter operational behavior and monitoring requirements. Facilities in Europe—or those exporting there—must align with both ISO classification and Annex 1 operational protocols.

ISO vs. USP <797> and <800>

USP <797> governs sterile compounding in pharmacies and hospitals, while USP <800> covers hazardous drug handling. Both reference ISO classifications (usually Classes 5–8) but add requirements for pressure differentials, segregated rooms, and cleaning procedures. ISO sets the baseline for air cleanliness; USP standards define how cleanrooms must be used and monitored in a clinical compounding context.

ISO vs. ISO 13485 and FDA 21 CFR Part 820

Medical device manufacturers must comply with ISO 13485 or the FDA’s Quality System Regulation (QSR), both of which require clean environments for device production. While ISO 14644 provides the standard for cleanroom classification, ISO 13485 focuses on quality systems, documentation, and risk management. ISO 14644 compliance supports the environmental control elements required under these broader quality frameworks.

Global Use and Adaptability

ISO 14644 is used globally, making it the de facto language of cleanroom compliance across industries. Its adaptability makes it suitable for pharmaceuticals, semiconductors, aerospace, and medical devices. While other regulations may specify operational behaviors, documentation, or product-specific controls, ISO provides the structural foundation that makes compliance possible.

For organizations designing facilities with global reach, ISO 14644 offers a unified framework that harmonizes with other regulatory expectations. By building to ISO standards first, companies create cleanroom environments that are easier to certify, audit, and operate across markets.

Industries That Rely on ISO Clean Room Standards

ISO cleanroom standards are not exclusive to any single industry. Their widespread adoption across diverse sectors is a testament to the flexibility and robustness of the ISO 14644 framework. From life sciences to advanced manufacturing, these standards serve as the backbone for maintaining environmental control where precision and contamination risk intersect.

Pharmaceutical and Biopharmaceutical Manufacturing

In pharma and biologics, cleanrooms are integral to the safe production of sterile injectable drugs, oral formulations, and advanced therapies. ISO Classes 5 through 8 are commonly used depending on the criticality of the operation. ISO Class 5 is essential for aseptic filling and open product handling, while Classes 7 and 8 are typically applied in formulation, staging, and gowning zones. ISO compliance supports FDA and EMA requirements and is often cross-referenced in GMP audits and filings.

Cell and Gene Therapy (ATMPs)

Advanced therapy medicinal products (ATMPs) require ISO-classified environments that support aseptic handling of genetically modified cells, viral vectors, or autologous patient materials. Cleanroom configurations in this field often include segregated ISO Class 5 PODs to reduce cross-contamination risks and maintain batch integrity. The high-value, high-risk nature of ATMPs demands cleanrooms that meet ISO standards and can support rapid reconfiguration as therapy pipelines evolve.

Semiconductors and Microelectronics

Microelectronics manufacturing requires ultra-clean environments to avoid particle contamination that can destroy circuitry. ISO Classes 3 through 6 are used in wafer fabrication, photolithography, and chip assembly. These facilities prioritize not only particulate control but also electrostatic discharge prevention and molecular contamination mitigation. ISO 14644 provides the framework for particle control, and supplementary standards may address molecular cleanliness and static shielding.

Aerospace and Optical Assembly

Precision components such as lenses, sensors, navigation systems, and satellite modules are manufactured in ISO Class 5 to 7 cleanrooms. Contamination during assembly can lead to mission failure or degraded performance in space or flight environments. Cleanrooms in this sector may also include vibration-dampening features and outgassing controls to meet unique aerospace requirements.

Medical Devices and Diagnostics

Medical devices, including implants, surgical instruments, and diagnostic kits, must be manufactured in controlled environments to ensure sterility and biocompatibility. ISO Classes 7 and 8 are typical, depending on the product and packaging stage. Compliance with ISO 14644 supports the environmental requirements of ISO 13485 and FDA 21 CFR Part 820, enabling manufacturers to meet global regulatory expectations.

Compounding Pharmacies and Hospital Labs

Cleanrooms for sterile compounding under USP <797> and hazardous drug handling under <800> must meet ISO classifications—typically ISO Class 5 for the primary engineering control and ISO Class 7 for buffer rooms. These environments are essential for protecting both patient safety and worker health, with ISO standards guiding air cleanliness and pressure zone requirements.

ISO cleanroom standards unify these sectors under a common language of environmental control, making it easier for manufacturers, regulators, and engineers to collaborate, certify, and scale operations worldwide.

Common Challenges in Achieving ISO Compliance

While ISO 14644 provides a clear and structured framework for cleanroom compliance, implementation can be complex. Organizations often encounter technical, operational, and strategic challenges that hinder their ability to meet and maintain ISO standards. Understanding these common pitfalls allows teams to address them early in the planning and operational cycle.

Inadequate Design Planning

A cleanroom’s ability to meet ISO classification depends heavily on initial design. Poor planning around airflow, pressure cascades, zoning, and HVAC sizing can result in particle infiltration and failure to meet required cleanliness levels. Common mistakes include underestimating air change rates, overlooking entry/exit protocols, or choosing inappropriate construction materials that shed particles or cannot be properly cleaned.

Misalignment Between ISO Class and Process Risk

Some facilities overdesign their cleanrooms by targeting stricter ISO classifications than required, driving up costs unnecessarily. Others underdesign, selecting a lower ISO class that does not adequately protect critical processes. Misalignment leads to either wasted resources or regulatory exposure. A risk-based approach should be used to align ISO classification with product sensitivity and process contamination risk.

Lack of Integrated Monitoring Systems

Monitoring systems are essential for proving and maintaining ISO compliance, yet many facilities treat them as an afterthought. Without real-time particle monitoring, differential pressure sensors, and environmental data logging, facilities cannot respond to deviations or demonstrate control to auditors. Retrofitting monitoring infrastructure after cleanroom completion can be costly and disruptive.

Operational Behavior and SOP Gaps

Even the best-engineered cleanroom can fail ISO standards due to human error. Improper gowning, incorrect door operation, and poor cleaning practices can introduce particles and jeopardize classification. ISO 14644-5 emphasizes the importance of procedural controls, training, and disciplined behaviors to complement technical infrastructure.

Inconsistent Maintenance and Requalification

ISO compliance must be maintained, not just achieved. Skipping scheduled requalification, deferring filter replacements, or neglecting HVAC performance testing can lead to classification drift over time. Facilities that do not implement preventive maintenance and requalification schedules risk losing control and facing costly remediation or shutdowns.

Documentation and Audit Readiness

In regulated industries, ISO compliance must be demonstrated with complete and accessible documentation. Facilities that lack documented protocols, testing data, or SOPs may technically comply but fail audits. This includes records for certification testing, monitoring logs, change control, and CAPA actions.

Addressing these challenges requires a multidisciplinary approach involving engineering, quality assurance, operations, and regulatory affairs. Working with experienced cleanroom suppliers—especially those that provide turnkey, ISO-classified prefabricated solutions—can reduce complexity and accelerate success.

Prefabricated Cleanrooms and ISO Compliance

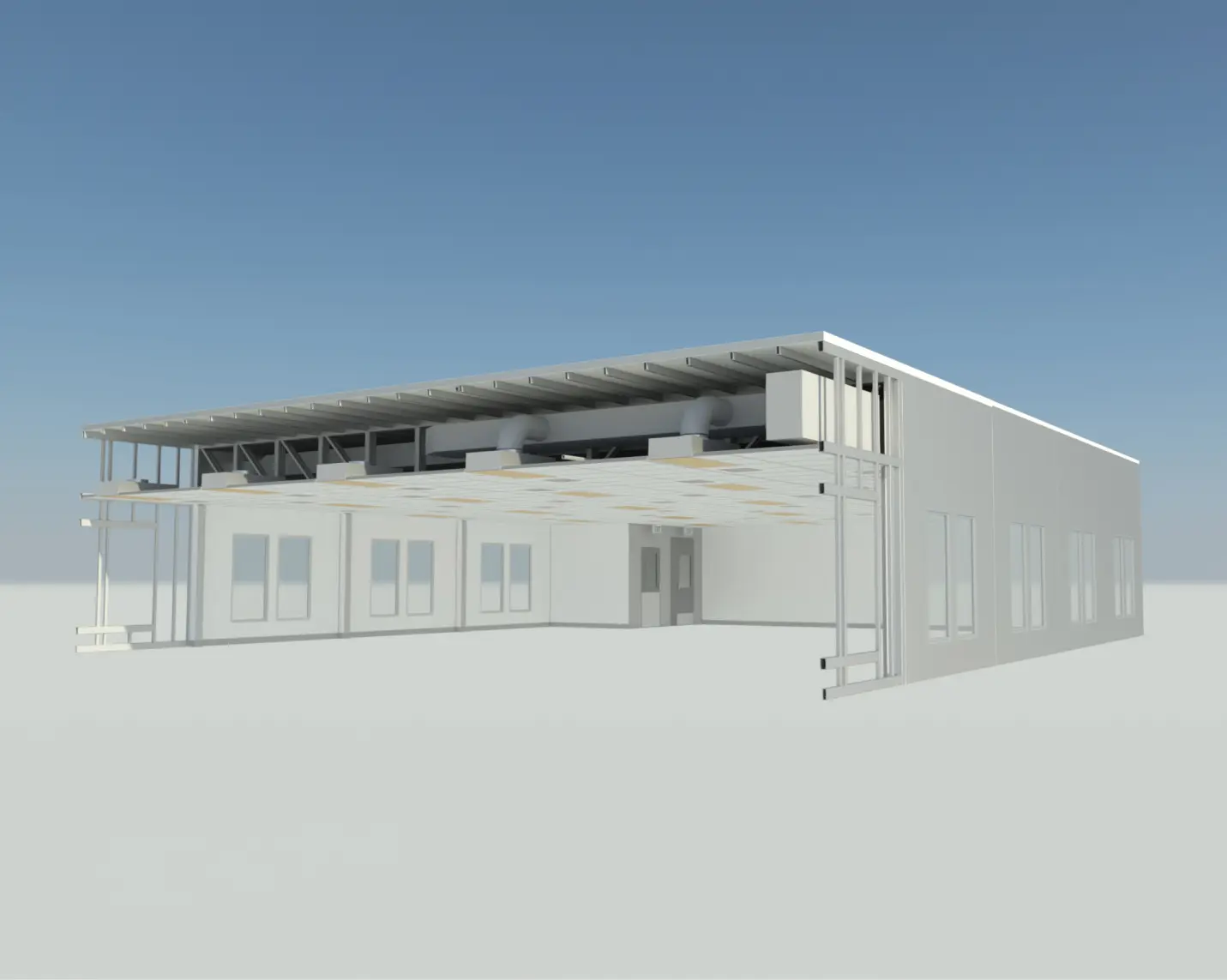

Prefabricated cleanrooms offer a modern, efficient, and scalable approach to ISO compliance by streamlining the design, build, validation, and operation phases. Unlike traditional construction, prefabricated cleanrooms are prefabricated in controlled factory settings, enabling greater precision, consistency, and quality control. These systems are engineered to meet specific ISO 14644 classifications and can be deployed rapidly while maintaining high levels of environmental performance.

One of the key advantages of prefabricated systems—like G-CON’s prefabricated PODs—is testing and design. Each POD is built to meet ISO Class 5, 7, or 8 specifications, and undergoes rigorous Factory Acceptance Testing (FAT) before delivery. This includes airflow visualization, HEPA integrity testing, particle count measurements, and pressure differential verification. FAT ensures that the cleanroom meets its ISO targets prior to installation, significantly reducing the burden of on-site commissioning.

Once delivered, prefabricated cleanrooms require minimal on-site integration. Site Acceptance Testing (SAT) confirms utility connections and environmental stability. Because the core systems—walls, HVAC, filtration, lighting, and monitoring—are integrated and validated during fabrication, IQ and OQ documentation is already partially complete, accelerating the qualification timeline and simplifying regulatory audits.

Prefabricated cleanrooms are also designed with long-term ISO compliance in mind. Integrated Environmental Monitoring Systems (EMS) and Building Management Systems (BMS) track pressure differentials, particle levels, temperature, and humidity in real time. These systems support ISO 14644-2 requirements for routine monitoring and allow facilities to maintain audit readiness without additional infrastructure.

Scalability is another key benefit. Prefabricated ISO-classified cleanrooms can be added, reconfigured, or relocated as operational needs change. This flexibility is especially valuable in dynamic industries like cell and gene therapy, where new processes and workflows must be accommodated quickly without sacrificing compliance.

By using prefabricated cleanrooms that are ISO-compliant by design, organizations can avoid common construction pitfalls, compress project timelines, and ensure consistent regulatory performance across multiple sites. G-CON’s prefabricated approach turns ISO compliance from a complex construction challenge into a turnkey deliverable—ready for operation, inspection, and production.

Conclusion: ISO Standards as the Foundation of Modern Cleanroom Strategy

ISO cleanroom standards serve as the foundation for building and maintaining contamination-controlled environments across life sciences, electronics, aerospace, and more. The ISO 14644 series provides not only a framework for cleanroom classification but also a roadmap for design, monitoring, testing, and operational excellence.

Organizations that follow ISO guidelines benefit from structured, internationally recognized standards that align with FDA, EMA, USP, and ISO 13485 requirements. By designing facilities around these standards, companies establish predictable environments, simplify qualification processes, and maintain continuous audit readiness.

Frequently Asked Questions About ISO Clean Room Standards

How often must ISO-certified cleanrooms be requalified?

ISO 14644-2 recommends requalification every 6 months for ISO Class 5 and annually for ISO Class 6–8 cleanrooms, or sooner if process or facility changes occur.

What’s the difference between ISO 14644-1 and ISO 14644-2?

ISO 14644-1 defines the particle concentration limits for cleanroom classification. ISO 14644-2 outlines the ongoing monitoring and requalification processes needed to maintain that classification over time.

Can a cleanroom meet ISO standards but fail a GMP audit?

Yes. ISO standards focus on air cleanliness, while GMP includes additional requirements such as microbial control, documentation, SOPs, and personnel behavior. ISO compliance supports GMP but is not sufficient on its own.

Are prefabricated cleanrooms ISO-compliant?

Yes. Leading prefabricated cleanroom manufacturers like G-CON design their systems to meet ISO 14644 standards. Prevalidation and integrated EMS/BMS systems ensure reliable performance and faster qualification.

Is ISO 14644 applicable to hospital or pharmacy environments?

Yes. USP <797> and <800> reference ISO Classes 5, 7, and 8. ISO 14644 provides the air cleanliness criteria for these facilities, supporting sterility and hazardous drug safety.