Aug 12, 2025

What Is an Aseptic Cleanroom?

Defining an Aseptic Cleanroom

An aseptic cleanroom is a controlled environment designed to prevent microbial contamination during critical manufacturing processes. It is essential for maintaining sterility in the production of pharmaceuticals, biologics, medical devices, and advanced therapies.

While all cleanrooms are built to control particulates, aseptic cleanrooms go a step further by minimizing viable microbial contamination. These environments are used when products must be sterile or manufactured under aseptic conditions before terminal sterilization.

Aseptic cleanrooms must comply with strict standards, including ISO 14644 classifications and Good Manufacturing Practice (GMP) guidelines such as EU Annex 1 and FDA 21 CFR Part 210/211. These standards govern airflow, personnel practices, equipment design, and environmental monitoring—each critical for aseptic processing.

Key Characteristics of an Aseptic Cleanroom

Aseptic cleanrooms typically require ISO Class 5 (equivalent to Grade A) conditions at the point of fill or exposure, with surrounding areas meeting ISO Class 7–8 (Grades B–C) standards. These environments enforce:

- Rigorous particulate and microbial control.

- High air change rates to dilute and remove contaminants.

- HEPA or ULPA filtration to maintain clean air supply.

- Laminar (unidirectional) airflow over critical zones to prevent turbulence and backflow.

These features help create a reproducible, validated space for aseptic manufacturing, minimizing risks to product integrity and patient safety.

Industries That Require Aseptic Cleanrooms

Aseptic cleanrooms are foundational to industries where sterility is not just a preference, but a regulatory and therapeutic necessity. These include:

- Pharmaceuticals: Especially sterile injectable drugs, ophthalmic solutions, and compounding pharmacies.

- Cell and Gene Therapy: Where live cells and viral vectors are especially vulnerable to contamination.

- Biologics and Vaccines: These require aseptic conditions from upstream bioreactors through final fill-finish.

- Medical Devices: Particularly those that are implantable or come into contact with blood or sterile tissue.

- Nutraceuticals and Food Products: Where sterilization is required for regulatory compliance or shelf stability.

Each of these sectors has strict regulatory oversight that demands consistently maintained aseptic conditions.

Aseptic vs. Sterile: What’s the Difference?

While often used interchangeably, “aseptic” and “sterile” have distinct meanings:

- Sterile refers to the absolute absence of viable microorganisms. A product is either sterile or not.

- Aseptic refers to the process by which contamination is prevented. An aseptic process ensures a sterile product remains sterile through critical steps such as formulation and filling.

Not all aseptic processes result in a sterile product unless terminal sterilization is applied. For example, many biological products are aseptically filled because they cannot withstand sterilization processes like autoclaving.

Contamination Control in Aseptic Cleanrooms

Controlling contamination in an aseptic cleanroom involves a multi-layered approach, targeting all possible sources:

- Personnel: The highest contamination risk, controlled via gowning protocols and limited access.

- Materials: Incoming components are sanitized and introduced through airlocks or pass-throughs.

- Equipment: Designed to be cleanable, non-shedding, and placed strategically to avoid airflow disruption.

Design features such as unidirectional laminar airflow, pressure cascade zoning, and gowning and degowning areas all contribute to maintaining aseptic conditions.

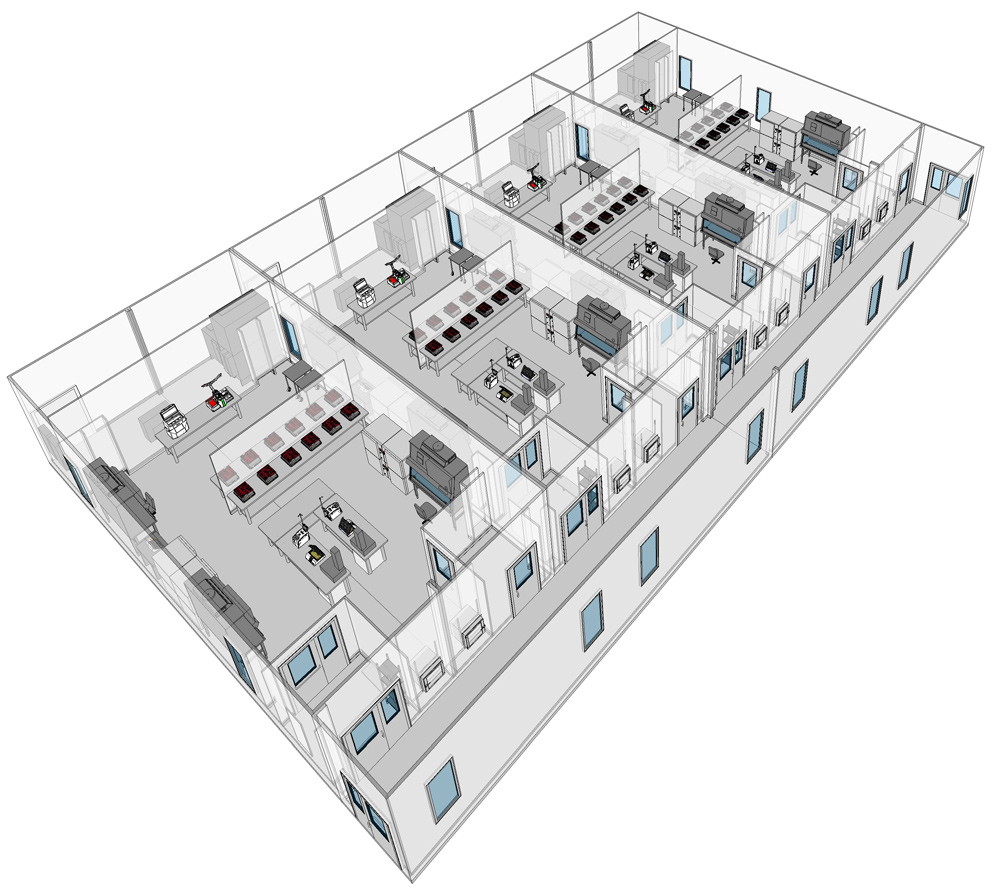

Design Principles of an Aseptic Cleanroom

The physical layout of an aseptic cleanroom directly supports contamination control. Best practices include:

- Zoning: Segregated clean and dirty areas, often with step-up/step-down room classifications.

- Flow Design: Dedicated personnel and material flows to prevent crossover.

- Construction Materials: Smooth, non-porous, non-shedding materials that resist microbial growth.

- HVAC Systems: Maintain positive pressure, humidity control, and temperature regulation.

- Monitoring Systems: Building Management Systems (BMS) and Environmental Monitoring Systems (EMS) provide real-time data on cleanroom performance.

Together, these design elements create a predictable, controllable manufacturing environment that supports aseptic compliance.

GMP and ISO Standards for Aseptic Cleanrooms

Aseptic cleanrooms are governed by international standards to ensure product safety:

- ISO 14644-1: Defines particle count thresholds by room class.

- EU GMP Annex 1: Specific guidance on aseptic manufacturing and cleanroom qualifications.

- FDA 21 CFR Part 210/211: U.S. cGMP requirements for finished pharmaceuticals.

- USP <797> and <800>: Guidelines for compounding sterile and hazardous drugs.

Compliance is demonstrated through validation procedures:

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

All systems must also be routinely revalidated, with thorough documentation maintained for audit readiness.

Prefabricated Aseptic Cleanrooms

Prefabricated cleanrooms are an increasingly popular solution for aseptic manufacturing environments due to their speed, repeatability, and GMP-aligned quality.

Advantages include:

- Off-site construction in controlled environments, reducing onsite contamination risk.

- Shorter project timelines compared to traditional stick-built facilities.

- Modular units that simplify installation and commissioning.

G-CON’s prefabricated POD® Cleanrooms are engineered to meet aseptic standards and can be deployed rapidly for both new facilities and cleanroom expansions. These units are particularly well-suited to pharma, biotech, and CGT companies looking to bring therapies to market faster while maintaining regulatory compliance.

Equipment and Technology in Aseptic Cleanrooms

To maintain aseptic conditions, cleanrooms employ advanced systems and equipment:

- HEPA and ULPA filters for high-efficiency air purification.

- Isolators and RABS (Restricted Access Barrier Systems) to limit human interaction during critical processes.

- Laminar airflow hoods to protect exposed products in critical zones.

- Environmental monitoring systems to track particle counts, microbial levels, and room conditions.

- Automation and robotics to reduce human presence and contamination risk.

As automation becomes more accessible, aseptic cleanrooms are increasingly integrating smart technologies to ensure consistent operation and regulatory visibility.

Operational Best Practices

Even with best-in-class design, aseptic cleanroom performance depends on consistent operational discipline:

- Gowning protocols: Multi-step procedures with visual checks to ensure complete barrier protection.

- Cleaning and disinfection: Performed on strict schedules with validated agents and methods.

- Personnel training: Routine retraining and qualification to maintain GMP standards.

- Preventive maintenance: Scheduled upkeep of HVAC, filtration, and monitoring systems.

Real-time environmental monitoring allows operators to catch deviations before they affect production quality.

Cost and Time Considerations

Aseptic cleanrooms are capital-intensive—but delays and noncompliance are even more costly. Choosing prefabricated cleanrooms helps offset these challenges:

- Faster build and installation times (often 40–60% shorter).

- Reduced need for onsite labor, especially important in regions with workforce shortages.

- Lower risk of rework or compliance issues due to offsite quality control.

- Scalable design minimizes the cost of future facility expansion.

These factors make prefabricated systems a cost-effective and compliant solution for aseptic operations.

Future Trends in Aseptic Cleanrooms

Aseptic cleanroom design is evolving in response to industry needs:

- Robotics and automation are replacing manual operations, improving repeatability and reducing contamination risks.

- AI-powered monitoring systems can predict and prevent deviations before they occur.

- Single-use systems simplify cleaning and validation for multi-product facilities.

- Energy-efficient designs and sustainable materials are gaining traction as environmental concerns grow.

Prefabricated aseptic cleanrooms are well-positioned to support these trends by offering adaptable, modular platforms that meet the changing demands of pharma and biotech production.

Conclusion: Why Aseptic Cleanrooms Matter

Aseptic cleanrooms are mission-critical for manufacturers who must prevent contamination, meet global regulatory requirements, and safeguard public health. They provide the infrastructure for high-quality production in pharmaceuticals, biologics, and medical devices.

Prefabricated cleanrooms, like those offered by G-CON, offer a validated, scalable, and cost-effective alternative to traditional construction. For companies navigating the complex world of aseptic production, partnering with G-CON ensures both compliance and agility in a competitive, highly regulated industry.

FAQ

What ISO class is required for an aseptic cleanroom?

ISO Class 5 (Grade A) is required at critical points such as filling or open processing, with surrounding areas typically ISO 7 or 8.

How is an aseptic cleanroom different from a sterile environment?

Aseptic environments prevent contamination during processing, while sterility refers to the final product being free of all viable organisms.

What industries use aseptic cleanrooms the most?

Pharmaceuticals, biotech, medical devices, and advanced therapies like cell and gene therapy rely heavily on aseptic cleanrooms.

How long does it take to build an aseptic cleanroom?

Traditional builds can take 15–30 months. Prefabricated cleanrooms can be delivered and installed in as little as 9–18 months.

Are prefabricated aseptic cleanrooms GMP-compliant?

Yes. G-CON’s prefabricated cleanrooms are designed and validated to meet global GMP and ISO standards for aseptic manufacturing.