Jul 01, 2025

Enhance Your Cleanroom with Honeycomb Panels

Transformative Efficiency and Compliance

Experience a breakthrough in cleanroom performance with our proprietary honeycomb panels. Designed by G‑CON, our panels optimize airflow and thermal regulation, ensuring your environment attains peak operational efficiency. Built with lightweight yet durable composite materials, they seamlessly support laminar flow while acting as a robust barrier against contaminants.

Technical Advantages

Our honeycomb panels enhance your cleanroom’s overall functionality:

• Optimized Airflow & Temperature Control: Precisely engineered geometry improves directional airflow and maintains thermal stability.

• Rigorous Compliance: Constructed in strict accordance with ISO14644 and GMP standards, these panels secure a certifiable clean environment.

• Material Excellence: The use of high-performance composites offers strength and flexibility, reducing installation complexity.

• Rapid Installation: The modular design enables swift integration, minimizing facility downtime and accelerating project timelines.

A Future-Proof Cleanroom Solution

By integrating our honeycomb panels, you elevate the reliability and efficiency of your facility. This innovation not only addresses present challenges but also anticipates future production requirements. Our panels are a cornerstone of scalable, adaptable cleanroom systems that empower your organization to stay ahead in a competitive landscape.

Our Commitment to Excellence

At G‑CON, our technical expertise and commitment to quality drive every design decision. We equip your operations with a solution that blends precise engineering with forward-thinking innovation, ensuring that your cleanroom remains compliant, efficient, and ready to support modern manufacturing demands.

What Advantages Do Honeycomb Panels Offer?

Superior Performance and Compliance

Our honeycomb panels redefine cleanroom environments by precisely managing both airflow and thermal regulation. The panels’ engineered structure creates uniform laminar flow and stabilizes temperature, ensuring consistent conditions critical to maintaining uninterrupted production for sensitive processes. Constructed from robust composite materials, these panels not only guarantee exceptional durability but also streamline installation and maintenance—minimizing downtime and operational interruptions.

Regulatory Excellence

Engineered in strict accordance with ISO14644 and GMP guidelines, our panels provide a proven framework for maintaining pristine cleanroom integrity. This design seamlessly meets and exceeds international regulatory standards, affording your operations an added layer of security and consistent compliance. With rigorous particulate control and adherence to industry standards, our solution safeguards against contamination risks while optimizing process fidelity.

Economic and Environmental Benefits

The inherent durability and modularity of our panels deliver significant cost advantages over the long term. Reduced maintenance needs, efficient installation processes, and lower labor requirements translate into tangible savings. In addition, the eco-friendly composition of the panels supports sustainable practices, aligning your facility with corporate environmental objectives and reducing your overall ecological footprint.

Seamless G‑CON Integration

At G‑CON, our expertise in modular cleanroom solutions ensures that these innovative panels integrate effortlessly into your facility. This forward-thinking design not only addresses current challenges but also anticipates future operational demands, offering a scalable solution that evolves with your organization’s needs.

How Are Honeycomb Panels Constructed?

Material Composition and Engineering Precision

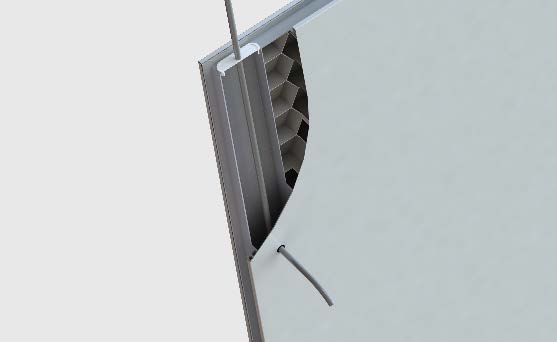

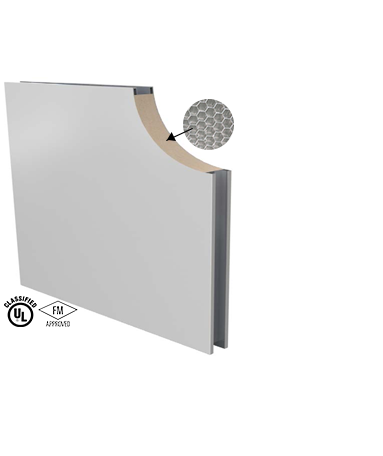

Our honeycomb panels are engineered with a robust core of lightweight aluminum or alternative high-efficiency materials. Sandwiched between ultra-high-strength composite skins, this design enhances structural durability and minimizes overall weight. The refined construction enables swift installation and reduces maintenance demands while providing a resilient barrier against environmental stresses.

Advances in Manufacturing Technique

Manufacturing innovations have transformed panel production. Precision engineering ensures uniform cellular geometry, which optimizes airflow and thermal regulation within your cleanroom. These advanced techniques support the stringent environmental conditions required in pharmaceutical and biotech settings, thereby safeguarding process integrity and operational reliability.

Eco-Friendly Construction and Sustainability

We prioritize sustainability by incorporating recyclable, low-impact materials into our panels. This eco-friendly approach not only minimizes your facility’s environmental footprint but also yields long-term cost benefits through reduced maintenance and enhanced energy efficiency. Such design choices align with modern corporate sustainability goals while delivering exceptional performance.

Performance and Integration Excellence

The lightweight yet durable structure of our panels facilitates rapid deployment and enduring reliability. At G‑CON, our innovative cleanroom solutions are seamlessly integrated into your existing infrastructure, providing a scalable, future-proof system that adapts to evolving industry demands without compromising quality.

Installation and Maintenance Best Practices for Honeycomb Panels

Installation Protocol

Prepare your cleanroom space by eliminating all debris and potential contaminants before initiating panel placement. Align each honeycomb panel with the designated framework using precision tools—such as laser alignment devices—to achieve exact positioning. Secure panels with industry-approved fasteners that maintain rigid structural integrity, while the inherent modular design simplifies integration with existing systems. For configuration specifics or custom adjustments, consult our dedicated technical support to access tailored guidance.

Maintenance Regimen

Routine inspection is vital for maintaining panel performance and compliance with ISO14644 standards. Experts recommend periodic checks of panel surfaces, joints, and fastener stability. Cleaning should involve non-abrasive solutions that preserve the integrity of the composite materials and optimize airflow management. Establish a systematic maintenance schedule, ensuring issues are detected and addressed before they affect operational performance.

Mitigating Maintenance Challenges

Should any panels exhibit signs of wear, immediate replacement is advised to uphold the stringent particulate control and cleanability requirements in critical environments. Our technical team provides remote assistance for troubleshooting and complex configurations, enabling seamless resolution of any installation or maintenance obstacles.

Strategic Optimization and Future Adaptability

Enhance the overall installation process by preassembling modular sections where applicable, reducing onsite labor and downtime. Implement a real-time monitoring system to track panel performance and schedule proactive maintenance. This approach not only preserves surface integrity but also supports future facility expansions and reconfigurations, ensuring your cleanroom continues to meet evolving industry standards while driving down operational costs.

Why Are Compliance and Standards Important?

Our cleanroom operations rely on rigorous adherence to protocols that ensure safety, environmental control, and uninterrupted production. At the heart of our technology, honeycomb panels are engineered to conform to ISO14644 and GMP guidelines, setting a robust framework for maintaining air cleanliness and proactive contaminant control. These stringent standards protect manufacturing processes by consistently upholding quality, reducing risk, and minimizing operational disruptions.

Compliance is fundamental for safeguarding your operations. Honeycomb panels are meticulously designed to meet and exceed regulatory mandates, protecting sensitive production areas through durable construction and precision engineering. This design not only satisfies legal requirements but also bolsters your reputation for uncompromised quality. Such operational integrity is crucial in high-stakes sectors like pharmaceutical and biotech manufacturing, where even minimal deviations can lead to significant financial and safety repercussions.

Risk management is integral to our approach, as it mitigates potential issues ranging from process interruptions to legal noncompliance. The resilient construction and advanced material composition of our panels provide stability and enhance safety by maintaining optimal environmental conditions. This proactive design ensures that every cleanroom functions reliably under the most demanding conditions.

At G‑CON, our commitment to standards is evident in our modular cleanroom solutions. We integrate advanced engineering with continuous quality monitoring, ensuring that our systems remain aligned with evolving industry directives. When you choose our honeycomb panels, you invest in a solution that not only meets today’s rigor but is also adaptable to tomorrow’s challenges, supporting sustainable growth and operational excellence.

Cost Efficiency and ROI of Honeycomb Panels

Economic Advantages

Investing in our honeycomb panels delivers robust financial benefits. Engineered from high-performance composite materials, these panels reduce installation time and lower labor expenses while minimizing maintenance cycles. Their resilient construction meets stringent ISO14644 and GMP standards, ensuring both durability and cost savings.

Operational Savings

Enhanced airflow and precise thermal regulation create a stable production environment that drives higher process productivity. With a design optimized for rapid deployment, our panels enable swift cleanroom upgrades that directly reduce operational downtime and energy consumption.

- Extended Lifespan: Durable materials minimize replacement frequency.

- Swift Integration: A modular design streamlines installation and reduces labor costs.

Return on Investment

By stabilizing critical cleanroom conditions, our panels boost output and decrease energy usage, yielding a measurable improvement in ROI. The enhanced environmental control they provide supports increased throughput and operational agility, allowing you to reinvest savings into further innovation.

Strategic Integration

At G‑CON, we seamlessly incorporate honeycomb panels into our modular cleanroom systems. This integration not only supports current operational needs but also positions your facility for future scalability and sustainability. By choosing our solution, you secure a cost-effective, eco-conscious upgrade that underpins long-term competitive performance.

What Customization Options Are Available for Honeycomb Panels?

Our advanced modular cleanroom systems empower you with bespoke honeycomb panels tailored precisely to your operational demands. Designed for seamless integration within your facility, panels are available in custom sizes and shapes that align flawlessly with your layout requirements. We offer a selection of premium materials—ranging from lightweight aluminum to high-performance composites—that not only ensure robust durability but also meet the rigorous ISO14644 and GMP standards.

Engineered for enhanced performance, you can choose to add features such as superior thermal insulation or acoustic dampening. These enhancements refine airflow management and temperature regulation while reinforcing particulate control. By selecting tailored features, you optimize environmental stability and streamline installation procedures. This precision-engineered customization minimizes future modifications and supports effortless facility expansion.

Our solution also incorporates forward-looking elements. Integrated IoT predictive diagnostics and sustainable material choices offer you significant long-term cost advantages. Customization thus not only addresses your current process needs, but it also anticipates evolving regulations and technological advancements, ensuring your cleanroom remains adaptive and resilient.

At G‑CON, we collaborate closely with you to define optimal configurations that enhance cleanroom functionality and operational uptime. Our technical team delivers a solution that is as dynamic as it is precise, empowering your organization with advanced, custom-engineered panels that support both current performance and future scalability.

Contact G-CON Today

Transform Your Cleanroom Operations

Experience a new era of cleanroom performance with G‑CON’s innovative honeycomb panels. Our advanced panels optimize airflow and thermal regulation while providing an unparalleled barrier against contaminants. Crafted using high-performance composite materials, they support uniform laminar flow and seamless integration into your facility.

Distinctive Advantages

Our solution delivers superior performance and regulatory excellence. Engineered to meet ISO14644 and GMP standards, our panels guarantee uncompromised particulate control and robust compliance in every installation. The streamlined design minimizes downtime and supports rapid deployment, ensuring your operations maintain peak productivity.

Comprehensive Support

We work closely with you throughout the entire project—from initial consultation to final installation. Our dedicated team customizes solutions to meet your specific cleanroom requirements, integrating state-of-the-art predictive diagnostics and sustainable materials that support your organization’s environmental objectives.

Begin Your Journey

Discover how our cutting-edge cleanroom enhancements can elevate your facility’s performance and adaptability. For expert guidance on customizing and integrating our panels into your infrastructure, please reach out to our technical specialists to explore tailored solutions designed for long-term operational excellence.

What Advantages Do Honeycomb Panels Offer?

Enhanced Operational Performance

Engineered to precisely manage airflow and stabilize temperature, our honeycomb panels significantly improve cleanroom performance. The optimized cellular geometry ensures a uniform laminar flow, essential for maintaining strict particulate control. Constructed from high-performance composite materials, these panels facilitate rapid installation and minimize facility downtime, resulting in seamless operational integration.

Superior Regulatory and Environmental Integrity

Meticulously designed to meet ISO14644 and GMP standards, our panels establish a reliable framework for cleanroom compliance. This adherence to international regulatory criteria not only safeguards process fidelity but also bolsters certification efforts. Furthermore, the panels’ eco-friendly composition supports sustainable practices by reducing energy consumption and maintenance requirements, aligning with your organization’s environmental initiatives.

Cost Efficiency and Scalable Integration

Investing in these panels translates to measurable cost savings. Their durable construction extends the lifespan of your cleanroom infrastructure, while the modular configuration simplifies installation and future reconfiguration. This strategic design minimizes labor costs and reduction in maintenance cycles, ensuring that your facility remains adaptable to evolving production demands.

Our commitment to integrating advanced engineering with forward-thinking design ensures that our honeycomb panels not only address current operational challenges but also anticipate future scalability needs. This results in a resilient, cost-effective cleanroom solution that stands at the forefront of industry innovation.

Why Are Compliance and Standards Important?

Ensuring Safety and Integrity

Our honeycomb panels are engineered to secure environments by maintaining unparalleled air cleanliness and precise contaminant control. By adhering strictly to ISO 14644 and GMP protocols, these panels construct a resilient barrier essential for pharmaceutical and biotech manufacturing. This rigorous standardization not only protects process integrity but also instills operational confidence.

Meeting Regulatory Standards

Designed to align with internationally recognized criteria, our panels proficiently satisfy regulatory mandates. They are formulated to deliver consistent particulate control and environmental stability, thereby ensuring uninterrupted cleanroom operations. Compliance is integral and becomes a strategic asset that reinforces trust and upholds quality benchmarks while simplifying audit and certification procedures.

Risk Management and Strategic Integration

Robust material composition and precision engineering mitigate risks associated with environmental fluctuations and unexpected disruptions. Our solution actively reduces the potential for costly process failures through dependable performance and consistent regulatory compliance. Enhanced safety protocols and sustainable material choices further diminish operational risk and drive long-term cost benefits.

Our Commitment to Excellence

At G‑CON, we integrate advanced engineering with a forward-looking approach to create modular cleanroom solutions that evolve with your organization’s needs. Our focus on unified regulatory adherence and comprehensive risk management delivers a platform for continuous operational improvement while safeguarding critical production processes.

This framework empowers your organization to achieve new levels of efficiency, safety, and market credibility.

How Are Honeycomb Panels Constructed?

Robust Material Composition

We design our panels with a lightweight core composed of high-grade aluminum or advanced composites. Encased in a dual-layer skin of resilient material, this structure delivers exceptional strength and superior resistance to environmental stresses. This engineered configuration directly supports stringent cleanroom parameters.

Cutting-Edge Manufacturing Innovations

Our manufacturing process employs precision engineering to create a uniform honeycomb structure that optimizes directional airflow and heat distribution. Advanced techniques ensure that each cell maintains consistent geometry, a critical factor in upholding controlled environmental conditions for pharmaceutical and biotech applications.

Sustainable and Eco-Conscious Design

We incorporate recyclable materials into our panels, reducing resource consumption while supporting your organization’s environmental commitments. This approach not only minimizes waste but also contributes to lower energy requirements and reduced maintenance over the lifecycle of the cleanroom system.

Performance-Driven Metrics

By combining a lightweight core with robust outer layers, our panels simplify installation and extend operational longevity. This integration results in reduced maintenance intervals and steady, reliable performance under high-demand conditions, ultimately enhancing process integrity and lowering long-term costs.

Advanced Integration with G‑CON Solutions

At G‑CON, our expertise in modular cleanroom innovation is embedded in every panel. Our products seamlessly integrate with your existing infrastructure, ensuring adaptability to evolving industry standards while maintaining exceptional regulatory compliance.

How Are Honeycomb Panels Installed and Maintained?

Installation Overview

Begin by clearing your designated cleanroom area of debris and contaminants. Prepare the framework and position each honeycomb panel carefully using precision alignment tools such as advanced laser systems. Our panels are designed to fit seamlessly into the existing structure; secure them with industry-approved fasteners arranged uniformly to maintain structural integrity. For complex layouts, consult our technical support to achieve precise alignment and ensure optimal performance.

Maintenance Guidelines

Regular inspections are critical. Examine panel surfaces, joints, and fasteners routinely to detect any signs of wear or damage. Clean each panel using non-abrasive solutions to preserve the integrity of high-performance composites, thereby maintaining the guidelines set by ISO14644 standards. Implement predictive diagnostics through IoT sensors to monitor real-time conditions and address issues proactively before they escalate, safeguarding environmental control.

Addressing Common Challenges

Precision in alignment is essential. Utilize specialized tools to achieve the exact configuration required for effective particulate control. Should any panel show damage or misalignment, resolve the issue immediately to prevent disruptions in your cleanroom’s contaminant barrier.

Optimization Strategies

Enhance installation efficiency by preassembling modular sections where possible, reducing onsite labor and downtime. Adopt a structured maintenance schedule based on real-time monitoring, ensuring longevity and uninterrupted compliance with cleanroom standards. This approach not only sustains robust performance but also facilitates future facility adaptations without compromising quality or regulatory adherence.

What Is the ROI of Honeycomb Panels?

Cost Efficiency and Savings

Our honeycomb panels deliver compelling value for your cleanroom infrastructure by streamlining installation and reducing long‐term maintenance expenditures. Designed with lightweight yet durable composite materials, these panels expedite setup and minimize labor while ensuring robust performance. Their engineered cellular structure promotes precise laminar flow and stable thermal regulation, which directly translates into improved environmental control and operational consistency.

ROI Analysis

By stabilizing airflow and temperature, our panels boost production reliability and reduce energy consumption. Enhanced process fidelity leads to higher throughput and lower operational interruptions, effectively increasing your return on investment. Key benefits include:

- Superior Durability: Engineered to endure rigorous operating conditions, reducing replacement frequency and maintenance overhead.

- Streamlined Deployment: The integrated design simplifies installation and supports rapid facility upgrades, curtailing downtime considerably.

- Optimized Energy Savings: Accurate thermal management lowers energy use, contributing to cost reduction over the system’s lifespan.

Long-Term Investment Impact

Adopting our honeycomb panels represents a forward-thinking investment. Their eco-friendly composition aligns with sustainability objectives by lessening environmental impact and supporting a green operational footprint. This commitment to sustainable design not only strengthens regulatory compliance but also elevates your organization’s market reputation for quality and responsibility.

Integrated G‑CON Advantage

Seamlessly incorporated into our modular cleanroom solutions, these panels enhance both current performance and future scalability. Our technical expertise ensures that every element is tailored to meet evolving industry demands while maximizing cost benefits and operational excellence.

Customization Options for Honeycomb Panels

Tailored Solutions for Diverse Operational Needs

At G‑CON, we design honeycomb panels that can be precisely customized to match your cleanroom’s unique specifications. Our panels are engineered in a range of sizes and configurations, ensuring they integrate seamlessly with your existing layout. You can choose from premium materials—such as lightweight aluminum or advanced composites—to meet both structural durability and weight requirements while satisfying ISO14644 and GMP standards.

Each panel may incorporate specialized features that enhance thermal insulation or provide acoustic dampening for optimal environmental control. By fine‐tuning the cellular geometry, we improve airflow management and temperature regulation, which are critical for maintaining a stable production environment. Custom modifications also enable rapid installation; our components are designed for preassembly and swift alignment using precision tools.

These adaptable solutions contribute significantly to sustainable operations by reducing material waste and maintenance expenses. Enhanced design flexibility means your cleanroom remains agile, capable of supporting future facility expansions or adjustments to emerging regulatory directives. This adaptability not only safeguards product integrity but also reinforces long‐term operational cost savings.

Our expert team works closely with you to define precise dimensional and performance criteria. The resulting configuration delivers a bespoke cleanroom solution that is both scalable and robust, ensuring your facility remains at the forefront of industry innovation. Embrace the power of appropriately tailored technology to drive superior performance and regulatory excellence in your cleanroom environment.