Jun 07, 2025

ISO 5 vs ISO 7

ISO 5 vs ISO 7: Understanding Cleanroom Classifications and Their Applications

Introduction: Understanding Cleanroom Classification in Biotech and Pharma

Cleanroom classification is a foundational concept in regulated manufacturing environments. Whether producing sterile injectable drugs, cell and gene therapies, biologics, or medical devices, manufacturers must adhere to strict environmental standards that control airborne particulate levels and microbial contamination. Two of the most common classifications encountered in the industry are ISO 5 and ISO 7.

Defined by ISO 14644-1, these cleanroom classes are based on the maximum allowable number of particles per cubic meter of air. ISO 5 represents a significantly cleaner and more controlled environment than ISO 7, and each plays a distinct role in manufacturing workflows depending on the risk level, process type, and regulatory requirements. From aseptic fill-finish lines to buffer prep rooms, understanding when and how to deploy ISO 5 and ISO 7 cleanrooms is critical to ensuring product sterility, meeting GMP compliance, and optimizing facility design.

This article explores the core differences between ISO 5 and ISO 7 classifications, where each is used, how they interact in facility zoning strategies, and why selecting the right classification level for each stage of production can protect product integrity while supporting operational efficiency. We’ll also look at how modular cleanroom platforms—such as G-CON PODs—make it easier to build, validate, and scale ISO 5 and ISO 7 environments, especially in fast-moving or multi-product facilities.

ISO 5 Cleanrooms: Definition, Requirements, and Use Cases

An ISO 5 cleanroom is one of the highest levels of air cleanliness defined by ISO 14644-1. It allows no more than 3,520 particles per cubic meter of air that are 0.5 µm or larger. This level of control is critical for processes where product exposure to the environment can directly compromise sterility, safety, or efficacy.

Environmental Specifications

- Max Particle Count: 3,520 particles/m³ (≥0.5 µm)

- Air Changes per Hour (ACH): 240–600 ACH, depending on room size and configuration

- Airflow Type: Unidirectional (laminar), with vertical or horizontal flow

- Filtration: HEPA or ULPA filters, often placed in ceilings above critical operations

- Monitoring: Continuous particle and pressure monitoring; viable sampling during operations

Typical Applications

- Aseptic Filling and Stoppering

- Sterile Filtration

- Open Manipulations of Sterile Drug Products

- Final Product Transfer in Sterile Packaging

- Cell Therapy Formulation

- Use Inside RABS or Isolators

ISO 5 conditions are often created inside controlled environments such as laminar airflow hoods, isolators, or restricted access barrier systems (RABS), all of which are typically located within ISO 7 background zones. These environments are validated and monitored according to strict regulatory guidance, including EU GMP Annex 1 and FDA aseptic processing guidelines.

Modular Cleanroom Implementation

ISO 5 cleanrooms are resource-intensive to build and maintain. Modular cleanroom providers like G-CON offer pretested ISO 5 PODs equipped with unidirectional airflow, integrated HVAC, and continuous monitoring systems. These PODs can be used for fill-finish suites, viral vector formulation, or precision biologics production and allow for faster deployment .

ISO 7 Cleanrooms: Definition, Requirements, and Use Cases

ISO 7 cleanrooms, while less stringent than ISO 5 environments, still offer a high level of particulate control and are widely used throughout pharmaceutical, biotech, and medical device manufacturing. ISO 7 allows up to 352,000 particles per cubic meter at ≥0.5 µm and is commonly used as a background or staging zone for ISO 5 operations.

Environmental Specifications

- Max Particle Count: 352,000 particles/m³ (≥0.5 µm)

- Air Changes per Hour (ACH): Typically ≥30 ACH

- Airflow Type: Non-unidirectional (turbulent), though laminar options are used in critical applications

- Filtration: HEPA filters; often ceiling-mounted with return air at floor or wall level

- Monitoring: Pressure differentials, temperature, humidity, and viable sampling

Typical Applications

- Background Environment for ISO 5 Aseptic Zones

- Buffer Rooms for Sterile Compounding

- Downstream Purification Areas

- Gowning Rooms Leading to ISO 5 Zones

- Media Preparation and Equipment Staging

- Cell Culture Expansion

ISO 7 rooms are often adjacent to ISO 5 areas, forming part of a graded cleanroom cascade. The integrity of the entire zone depends on maintaining pressure differentials, consistent airflow, and effective gowning protocols to protect the cleaner space.

Modular Cleanroom Implementation

Because ISO 7 cleanrooms are required in nearly every sterile manufacturing facility, modular solutions like G-CON PODs are commonly deployed as configurable ISO 7 suites. These may house buffer prep, purification systems, or as background zones for ISO 5 aseptic fill-finish units. Modular construction allows companies to scale ISO 7 capacity rapidly and align zoning with their operational needs without disrupting validated areas.

ISO 5 vs ISO 7: Key Differences at a Glance

While both ISO 5 and ISO 7 cleanrooms are essential to regulated manufacturing environments, they serve distinct purposes and operate under different environmental requirements. Understanding the differences between the two is critical for facility zoning, process qualification, and regulatory compliance.

Air Cleanliness

- ISO 5: Maximum of 3,520 particles/m³ at ≥0.5 µm

- ISO 7: Maximum of 352,000 particles/m³ at ≥0.5 µm

ISO 5 is 100 times cleaner than ISO 7, making it suitable for operations where direct product exposure occurs.

Air Changes per Hour (ACH)

- ISO 5: Typically 240–600 ACH

- ISO 7: Minimum of 30 ACH

ISO 5 environments require significantly more filtered air to maintain particle control, resulting in higher energy consumption and HVAC complexity.

Airflow Design

- ISO 5: Laminar (unidirectional) airflow

- ISO 7: Typically turbulent airflow, though laminar may be used in critical zones

ISO 5 environments rely on vertical or horizontal laminar flow to continuously sweep particles away from the critical process area.

Applications

- ISO 5: Aseptic fill-finish, sterile filtration, open manipulations of sterile products

- ISO 7: Buffer rooms, equipment prep, background for ISO 5 zones

ISO 7 supports ISO 5 operations by acting as a cleaner staging environment with reduced contamination risk.

Construction Complexity and Cost

ISO 5 cleanrooms are more complex and expensive to design, build, and maintain. Modular ISO 5 PODs, such as those provided by G-CON, streamline this process by offering solutions with integrated airflow and monitoring systems. ISO 7 PODs provide a balance of performance and affordability and are often the backbone of scalable modular cleanroom strategies.

Zoning Strategy: How ISO 5 and ISO 7 Work Together in GMP Facilities

In a typical GMP-compliant cleanroom facility, ISO 5 and ISO 7 environments are strategically layered to create a cleanroom cascade—moving from lower to higher cleanliness levels as personnel and materials progress toward critical manufacturing operations. This zoning model supports contamination control, process segregation, and regulatory readiness.

Typical Cleanroom Cascade

- ISO 8 (Ante-Room or Outer Gowning Area)

- ISO 7 (Buffer Room or Inner Gowning Area)

- ISO 5 (Aseptic Processing Area)

Each zone enforces positive pressure relative to the previous, ensuring that air flows from cleaner to less clean spaces and not in reverse.

Personnel Flow

Operators typically gown in stages—donning scrubs or coveralls in ISO 8, sterile gowns in ISO 7, and gloves or additional sterile gear before entering ISO 5 zones. Airlocks and interlocks are used between zones to prevent pressure disruptions and particle migration.

Material Flow

Raw materials enter through controlled airlocks or pass-through cabinets and are wiped or sprayed with disinfectants before entering ISO 7 zones. From there, they may be staged or transferred into ISO 5 environments depending on process needs.

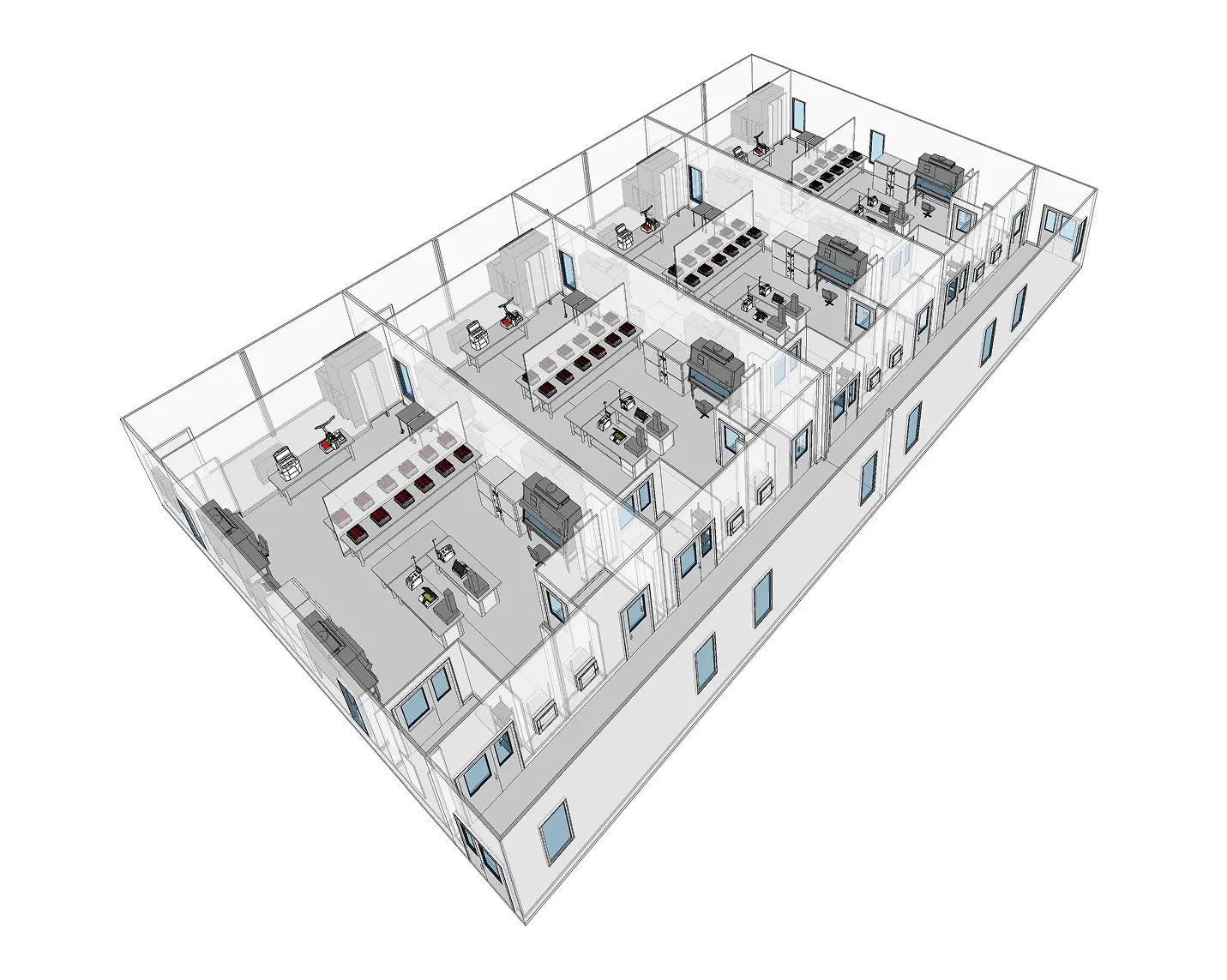

Integrated Modular Zoning

In modular cleanroom architectures, each ISO class can be isolated into individual PODs. For example, an ISO 7 POD may function as a dedicated buffer room, feeding into a neighboring ISO 5 POD used for aseptic filling. G-CON PODs allow this zoning model to be fully realized, with pressure-controlled interconnections, built-in EMS monitoring, and separate HVAC for each unit. This design enhances compliance and simplifies contamination control while allowing rapid deployment and reconfiguration.

Regulatory Alignment

Both FDA and EU regulators require a clear zoning strategy for aseptic processing. ISO 5 conditions at the point of product exposure must be supported by ISO 7 environments with validated pressure cascades, air change rates, and environmental monitoring. Facilities that can clearly demonstrate their zoning strategy through physical layout, SOPs, and monitoring data are far better positioned for successful inspections and long-term operational success.

Choosing the Right Cleanroom Classification Strategy

ISO 5 and ISO 7 cleanrooms serve fundamentally different—but equally vital—roles in regulated pharmaceutical and biotech manufacturing. ISO 5 environments are reserved for the most critical operations, such as aseptic filling and sterile filtration, where any contamination can directly compromise patient safety. ISO 7 spaces act as the protective barrier and controlled staging area that ensures ISO 5 conditions are properly maintained.

Effective cleanroom facility design doesn’t treat ISO classes as isolated specs—it integrates them into a cohesive zoning strategy. Understanding when, where, and how to apply ISO 5 and ISO 7 classifications allows manufacturers to ensure compliance, protect product quality, and optimize operational efficiency.

For organizations designing or upgrading facilities, especially those scaling up for clinical or commercial manufacturing, modular cleanroom platforms provide a streamlined path forward. Pretested ISO 5 and ISO 7 PODs allow you to deploy compliant zones faster, reduce project complexity, and configure layouts that align with evolving process needs and regulatory requirements.

Strategic Takeaways

- Use ISO 5 for operations involving open product exposure or aseptic manipulations.

- Use ISO 7 as the background environment supporting ISO 5, as well as for buffer rooms, downstream processing, and inner gowning areas.

- Maintain appropriate air change rates, pressure differentials, and airflow patterns to comply with ISO 14644-1 and GMP expectations.

- Design facility zoning to support unidirectional flow of personnel, materials, and waste.

- Consider modular cleanrooms to scale or adapt ISO-classified space without construction delays or revalidation disruptions.

If you’re evaluating cleanroom classifications for a new build or facility expansion, consider how ISO 5 and ISO 7 zoning decisions will impact compliance, risk, and operational flexibility. Modular cleanroom systems give your team the ability to deploy validated spaces faster and with less disruption—enabling better outcomes at every phase of manufacturing.

Frequently Asked Questions: ISO 5 vs ISO 7

How much cleaner is ISO 5 compared to ISO 7?

ISO 5 allows 3,520 particles per cubic meter (≥0.5 µm), while ISO 7 allows 352,000—making ISO 5 100x cleaner in terms of airborne particulate control.

Do I need both ISO 5 and ISO 7 in my facility?

Yes, for aseptic operations. ISO 5 is required where sterile products are exposed, and ISO 7 serves as the required background zone in most regulatory frameworks.

Can modular cleanrooms meet ISO 5 and ISO 7 requirements?

Yes. Modular cleanrooms can be engineered and validated to meet ISO 14644-1 classifications and cGMP standards. Each POD can be independently controlled, monitored, and certified.

What kind of operations take place in ISO 7 rooms?

ISO 7 cleanrooms are used for downstream processing, inner gowning, buffer and media prep, and as background for ISO 5 zones such as fill-finish operations.

How do I validate ISO 5 and ISO 7 cleanrooms?

Validation includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), along with routine monitoring of particle counts, microbial presence, differential pressure, and air change rates.